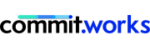

The Last Planner System (LPS), also called Collaborative Planning or Pull Planning is a project production workflow that delivers maximum value with minimal waste. This system empowers frontline leaders and crews to take an active role in planning and execution. Built on the principles of continuous improvement, it creates a more reliable, efficient workflow and improved outcomes. LPS aligns closely with familiar improvement principles like DMAIC (define, measure, analyse, improve, control), PDCA (plan, do, check, act) and SIC (short interval control).

Who is a Last Planner in Mining Operations?

A Last Planner is the person closest to the work with the authority to make decisions and commitments about the schedule and tasks to be done. The system improves project flow through collaborative planning that focuses on what should be done, what can be done, what will be done, what was done and what can be learned. As the timeline approaches execution, plans should become more detailed and responsive. This ensures work is both achievable and valuable.

In mining, the last planners would include supervisors, shift bosses, undermanagers, and crew leaders. These people are responsible for the work in greatest detail, closest to delivery with the greatest context to support decision-making. Planning should happen regularly – weekly, daily, and shiftly. It should involve short, focused discussions or meetings that build commitment to the schedule. Rather than a top-down approach, these meetings promote teamwork, accountability, ownership, and commitment to both shared and individual KPIs.

This collaborative approach enhances efficiency by aligning teams. Tasks only begin when enabling tasks are complete and resources are ready. LPS identifies potential conflicts early by visualising and planning for environmental conditions, resources, dependencies, enablers and prerequisites.

Although originally developed by Glen Ballard and Greg Howell for the construction industry, LPS has been successfully adapted for many fields including mining, software development, product design, education, and supply chain management.

Last Planner System and Technology

Today, technology plays an increasingly important role in enabling its implementation and real-time coordination across complex mining operations. Commit Works has developed CiteOps to ensure that the right people do the right work at the right time. Technology can help link the action and focus of frontline teams with higher level plans. When tech tools support the successful management of people, resources, and processes, mines can drive operational excellence .

Download the Commitment System Handbook for Underground Coal to learn more.