commit to operational excellence

Operations Planning & Execution

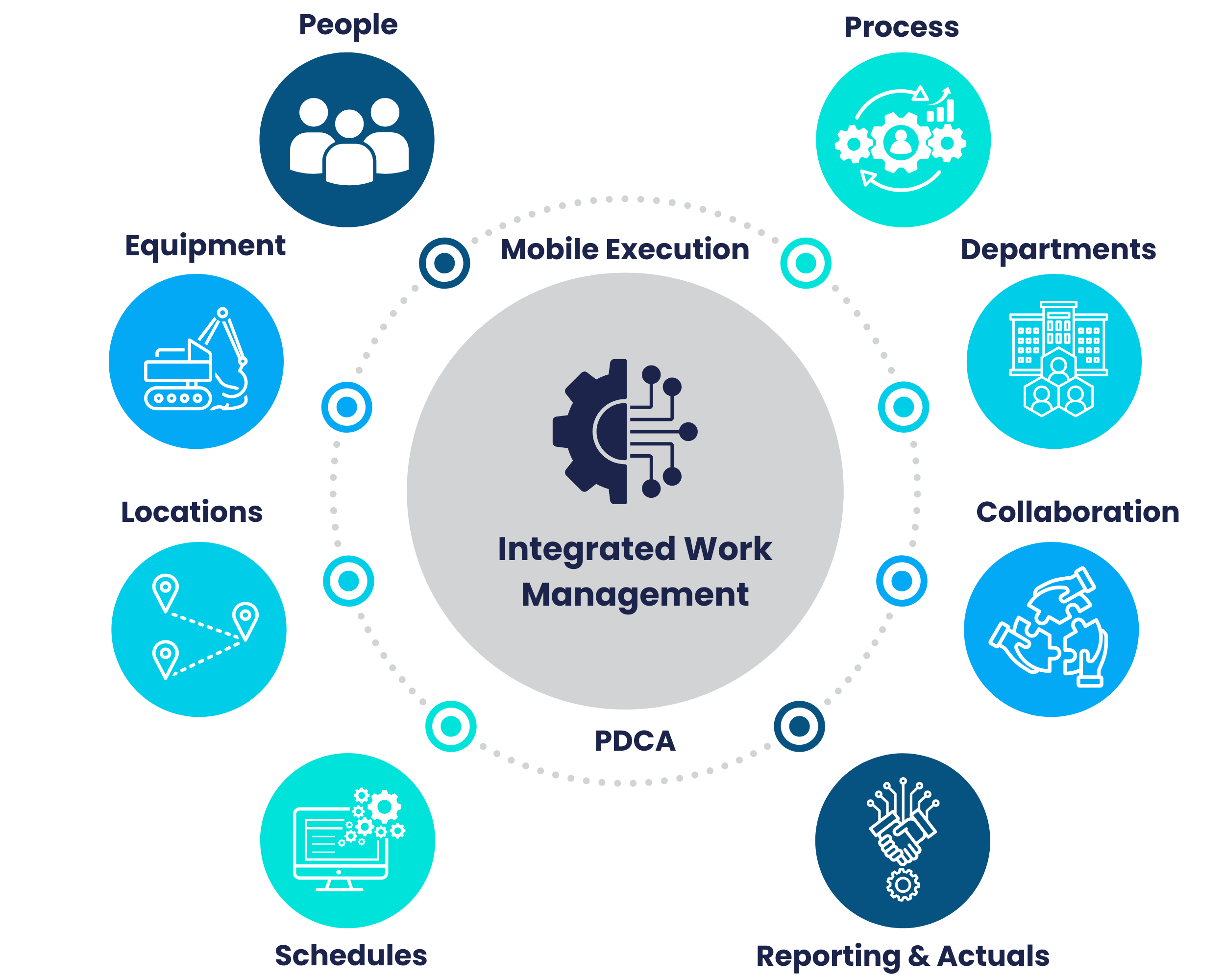

Our enterprise-grade software suite, designed for mining and metals companies, enables efficient planning, tracking, and execution of operational activities in one integrated platform. Through dynamic planning, better resource allocation, and real-time adjustments, our solution enables clear work visibility, enhances team coordination, and drives sustainable performance improvements.

Helping Mining Teams Stay Aligned and Productive

Increased

Productivity

Reduce delays and keep teams aligned.

Decreased

Costs

Minimise inefficiencies across planning & execution

Improved Safety & Compliance

Ensure informed, risk-aware decision-making

Better Customer Experience

Enable seamless coordination and reliability

A Unified Work Management Platform

Commit Works brings all operational planning and execution into one connected system – CiteOps. By centralising task management, it gives teams a clear, structured way to plan, track, and execute work efficiently. Real-time data and feedback loops drive continuous improvement, ensuring teams stay aligned and operations run smoothly.

Digital Short Interval Control (SIC) System

Commit Works’ SIC capability enables teams to monitor shift progress in short intervals, using real-time data to make informed decisions. It centralises task updates, automates routine tasks, and improves collaboration. This helps operations quickly respond to deviations, ensuring shifts stay on track and performance improves.

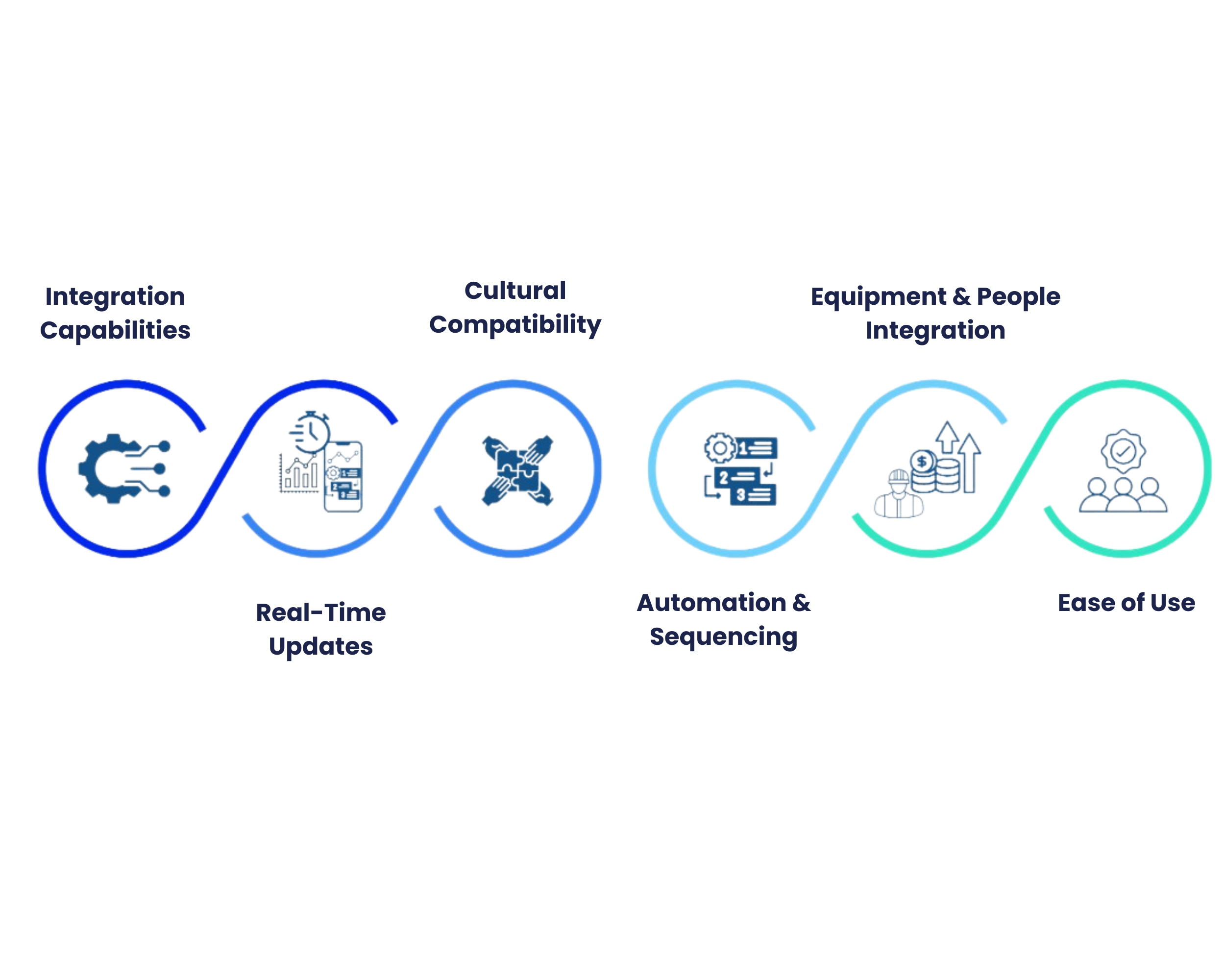

Dynamic Resource Management

Our software provides real-time visibility into people, equipment, and materials, ensuring efficient resource allocation across operations. The system helps teams plan shifts effectively, respond to changing conditions, and minimize downtime. Operations run smoothly when resource availability and utilisation is optimised.

Commit to Operational Excellence

Benefits

Our purpose built software suite helps mining operations boost productivity through better planning, coordination, and execution.

Operational Visibility

Gain comprehensive oversight of all operational activities even cross functional in real-time, enabling better decision-making and proactive issue resolution.

Shift-Level Control

Monitor and manage tasks on a per-shift basis, ensuring optimal resource allocation and immediate adjustments to maintain efficiency.

Performance Tracking

Gain visibility into task execution and workforce productivity with performance tracking. Identify bottlenecks, optimise resource allocation, and drive continuous improvement with actionable insights.

Safety & Compliance

Ensure adherence to safety protocols and regulatory requirements through integrated tracking and reporting features, enhancing workplace safety.

Timely Reports

Receive accurate, up-to-the-minute reports on operational performance, facilitating informed decision-making and strategic planning

Accessible through all devices

Frontline workers can access the digital shift plans on their Big Screens, Tablets & Mobile Phones, ensuring they have all the necessary instructions for their shift.

Key Capabilities

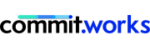

Integrated Work Management

Bring together different aspects of work within a unified system.

Short Interval Control

Make quick, informed decisions based on up-to-the-minute data.

Shift Planning

Optimise shift planning to ensure each shift is properly equipped according to operational demands

Resource Availability Planning

Ensure personnel, equipment, and materials are allocated efficiently to align with planned operations.

Operations Reporting

Reporting and visualisation tools for detailed operational insights and data-driven decision-making.

Production & Project Works Scheduling

Customisable Gantt scheduler displays location, equipment, personnel dependencies, or any task attribute combination.

Operations Planning Collaboration

Facilitate collaborative planning with shared data and task management tools for better team alignment and efficiency.

Plan-Do-Check-Act (PDCA)

Foster a culture of continuous improvement, ongoing refinement and sustainable performance enhancement.

Mobile Operations Execution

Support execution with a flexible, responsive tool to enable real-time data access and updates via mobile apps.

Resource utilisation

Maximise the use of people, location, equipment and material across operations.

Optimising Operations Outcomes

Harness performance metrics to continuously refine operations.

Prompted Data Acquisition

Utilise advanced data capture techniques.

Production Data Capture

Capture real-time data from production operations.

Digital Mine Operating System (dMOS)

Digitise the mine operations leveraging our purpose built technology.

High Availability (Cloud-Native)

Leverage modern cloud infrastructure for scalable, resilient operations, ensuring high availability and workload adaptability with Kubernetes.

Operations Digital Twin

Create a virtual model of operations, enabling scenario simulation and optimization to enhance planning and minimise real-world risks.

Integration

Enable seamless IT-OT integration with smart APIs and imports for efficient data exchange and process automation.

Cybersecurity

Enforce enterprise-grade security and compliance, safeguarding operational data and ensuring system integrity.

Operations Planning Automation & Optimisation

Automate recurring operational tasks to enhance efficiency and ensure consistent, optimised planning activities.

The digital backbone of mining operations

As our customers say, ‘If the operations plan isn’t entered in CiteOps, activities cannot be effectively tracked and optimised.’

3,818+

Tasks tracked per shift across global mining and metals operations.

8,162+

Personnel managed with verified skills and qualifications

35,655+

Locations tracked for better control of operational activities.

2,250+

Mobile App downloads for on-the-go plan control, even offline.

Trusted by the world’s leading mining companies

CiteOps is designed for key mining industry verticals

Underground Hardrock

Utilise a tailored software for efficient hardrock mining operations.