Short Interval Control and the Pathways to High Performance Mining

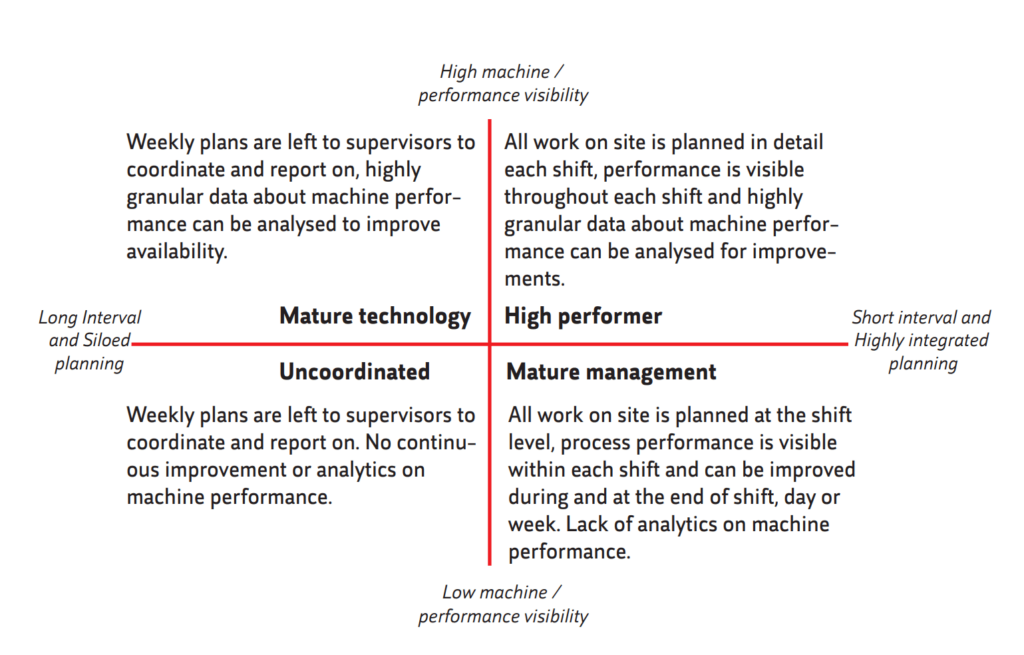

A few nights ago I had a call with Leon Cosgrove from Wipro about short interval control. We discussed the different routes miners can take to improve performance in their operations. Perhaps it was because we’re both involved in the consulting industry but somehow a 2 by 2 matrix appeared as we spoke. See above, we both thought it was helpful for describing the journey to a high performing operation.

On the Y Axis is the extent to which the mine can measure and see where all their equipment is and what it is doing. There is a big range of technologies here. To keep it simple these range from sites with no way of knowing where anything is or what it is doing through truck counts and radio based tools like PitRam up to high precision fleet management systems like Modular, Newtrax or MobileARIS. Telematics and measurement are one thing but getting the data out of the pit is equally challenging. Simplifying terribly, technologies used range from nothing, to radios, to leaky feeder to wifi and daisy chaining to LTE.

On the X Axis is the extent to which the mine is planning and scheduling frontline operational work. On the left are operations that believe that a good mining schedule. Perhaps a maintenance plan can be simply handed down to operations to execute. On the right are the operations who have the frontline management systems and behaviours necessary to describe in short intervals what needs to be done each shift for everyone on the site. These operations engage religiously in the Plan Do Check Act cycle and use variances from the plan each shift, day and week to drive performance improvements continuously.

Three pathways to high performance

With the matrix above it was interesting to think through the different routes to becoming a high performer, we developed three pathways to high performance.

1.Technology first. Many operations have invested heavily in connectivity and fleet management systems. They know where their machines are and exactly what is happening. When these operations want to increase performance, they have lots of high quality data. This is not enough. They still need to break silos and perform short interval, integrated planning and scheduling.

2. Management first. Traditional management operating system (MOS) consultants have done huge numbers of projects with miners. MOS implementation can improve frontline management, planning and coordination. Short interval control is a tool often implemented during these projects. However, without an easy to use and integrated system (most of these consultants still sell spreadsheets and whiteboards), mature behaviours are difficult to sustain. Operations that use this approach are difficult to sustainably move into the high performer quartile. Tools and systems often break when consultants leave.

3. Management and Technology together. The most direct route to high performer is integrating mature management practices with mature technology. Organisational behaviours are directly supported by – and embedded in – the way the technology works. Critical to this transition is the use of a fully integrated frontline planning and short interval control system. This can connect enterprise planning systems to the operational technology that runs the mine. Done well, this type of project uses mature management consultants to improve management practices while the technologists build a system to support mature behaviours. This approach delivers rapid and sustainable results for much lower cost than option 1 or 2.

Short Interval Control and CiteOps

Commit Works has been working with some of the largest and the smartest miners in the world to deliver massive production and safety improvements. Read our take on Operational Excellence here as we double-down on our commitment to high performance

Our fully integrated frontline planning, scheduling and short interval control system, CiteOps, has delivered 25% to 50% performance improvements in less than 3 months from implementation on mine sites. Many sites have sustained their results for years through management and ownership changes.

Commitment to High Performance

Many mining and metals operations struggle with planning and short interval control. To be successful, operations need a high-trust, high-commitment culture. Leaders should set clear expectations, teams negotiate realistic commitments, and everyone must contribute to practical, outcome-focused plans. When work is coordinated across functions, adapted transparently as conditions change, and continuously improved through the PDCA cycle, change is inevitable. By addressing root causes and using technology to enhance processes and productivity, organisations create aligned, accountable cultures that deliver exceptional results for employees, customers, communities and shareholders.