Short Interval Control

Enhance operational efficiency with Commit Works’ Short Interval Control solutions for mining. Monitor performance in real-time, make data-driven decisions, and improve productivity.

Unlock Mining Operational Efficiency with Short Interval Control

In today’s dynamic and fast-paced operations environment, mining and metals companies actively seek ways to enhance operational efficiency and productivity. Short Interval Control (SIC) empowers teams to make timely, data-driven decisions. This page explores core principles of Short Interval Control, highlights its impact on operational processes, and shows how Commit Works software helps the mining industry unlock performance gains.

What is Short Interval Control?

Short Interval Control (SIC) is a management methodology that focuses on short intervals, typically from a few hours to days. Unlike traditional long-term planning, SIC helps teams respond to real-time conditions. Mining operations can track key performance indicators, identify issues early and make rapid, informed adjustments.

Key Principles of Short Interval Control (SIC)

Continuous Monitoring

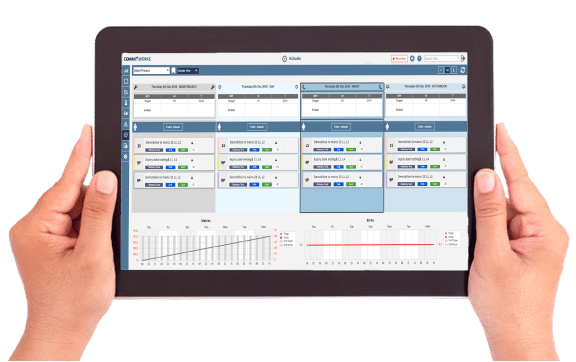

SIC relies on continuous monitoring of operational processes and execution performance. Teams use a range of tools including paper-based systems, radio communications, cloud and mobile technology, advanced sensors, data analytics, and monitoring systems to access real-rime performance metrics. Commit Works brings these capabilites together through its integrated digital tools including the CiteOps Planning Board, Gantt Scheduler, and Production Data Capture. The platform supports offline functionality, making it ideal for remote, underground, deskless or intermittently connected environments.

Defined Short Intervals

Decision Support

A core principle of SIC is the ability to take action when variations or issues are detected. This requires agile decision-making and a responsive organisational culture. Commit Works software brings visibility to progress of every shift, providing decision support for timely action. Planned vs actual status of work can be visualised on large screens in prominent areas of the operation, used to run regular performance review meetings, or monitored live on mobile devices.

Cross-functional Collaboration

SIC promotes collaboration across departments and teams. CiteOps optimises communication channels, ensuring information flows freely. This facilitates quick problem-solving and decision-making. CiteOps is designed to be deployed across as many operational work processes as possible for maximum collaboration. Field personnel / operators, contractors, production planners, strategic planners, superintendents, mine control operators, shift bosses / supervisors, maintenance planners, mine managers, and mine executives can all collaborate in our centralised system across all the work areas and activities.

Continuous Improvement

SIC is not a one-time fix; it’s an ongoing process of continuous improvement. Mines that use Short Interval Control are committed to analysing results, learning from them, and implementing changes to enhance efficiency. Commit Works software can be deployed to operations quickly across target teams and workstreams, then extended across more teams over time.

What makes Short Interval Control a key capability for mining operations?

Short Interval Control (SIC) is pivotal for its ability to enhance operational agility and efficiency in mining. CiteOps provides tools for continuous monitoring and decision-making. It enables mines to stay ahead of potential issues and optimise performance. Integrated into Commit Works software, SIC supports a dynamic approach to managing mining and metals operations, ensuring every decision is informed by the latest data.

Applications of Short Interval Control in Mining and Metals Sector

Mining & Production

Short Interval Control (SIC) in mining to optimises production schedules, reduces downtime, and improves overall equipment efficiency (OEE). Timely data allows for better production planning and resource allocation. CiteOps provides planning capabilities as well as actual production data capture. This means production schedules can be refined, realigned, and improved based on actual operations progress and feedback. CiteVis provides real-time operations reporting capabilities. KPIs can be reported and visualised in various ways. Reports can be run on-demand and/or emailed automatically.

Project Work

SIC is valuable in project work to ensure that timelines are met, resources are utilised efficiently, and potential issues are addressed promptly. While SIC focuses on detailed execution tasks of the shift, all of these detailed work tasks would be part of an overarching continuous or non-continuous production or project work process. CiteOps keeps track of all of the details of the shift, but also how the shift plans and results impact statuses and progress of overarching plans. CiteOps tasks are designed to run across multiple shifts, and standard tasks can be designed for standard processes.

15+

Mine Sites

5000+

Active Users

300+

Mobile Devices

1000+

KPI's Tracked