Despite a decade of continuous improvement and technological advances, global mining operations are up to 28% less productive. If we are smarter and better equipped than ever, why is productivity decreasing?

McKinsey notes that mines employing innovative technologies to generate lasting value could see productivity skyrocket. One of the key elements of operational excellence is the integration of operating systems to support and deploy the right practices and the right behaviours. Top-tier miners are leading the way. Rio Tinto’s Safe Production System (RTSPS) and BHP’s continuous improvement-driven BOS reveal how leadership and systems thinking reshapes performance.

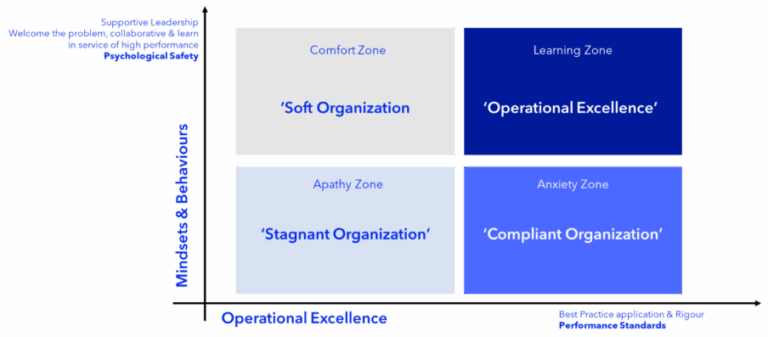

According to a 2023 study published in Sustainability, the most productive modern mines now include intelligent management and real-time decision-making. Scheduling management is crucial for optimising productivity. A well-implemented operating system leverages technology like CiteOps to ensure that every shift, every crew, and every leader knows the plan.

Implementing shift-level execution software is key to ensuring that clear, mine-wide targets are met. When feedback loops and data-driven decision-making are employed, potential production losses, inefficiencies and safety implications can be addressed as they arise.

The cause of management-system failures is often culture. Successful mining operations measure how business culture improvements feed excellence. Investments in software and technology can accelerate and deepen the cultural change needed to achieve operational excellence. Strong culture combined with a robust operating system delivers digital transformation at scale.

Operational excellence with CiteOps

CiteOps delivers an integrated approach to operational execution, ensuring that frontline teams are focused on executing tasks that drive compliance to short, medium and long term mine plans.

Productivity is imperative for tier-one miners. Leaders in the industry set the tone and expectations for culture change, technology adoption, and ultimately, success. This takes commitment. At Commit Works, we help mining operations commit to operational excellence. We drive performance optimisation through aligned workplans, accountability, and a continuous improvement culture.

In part one of our series on operational excellence, we delve deeper into the differentiators that drive mining performance. Download the pdf article here, or keep scrolling to read.

Part 1: What Sets Operations Apart – The Golden Thread You Didn’t Know You Needed (Until Now)

The answer to unlocking productivity isn’t more tech; it’s recognising and mastering the foundational operational thread that holds the key to efficiency.

The secret to reversing this decline isn’t about what tech you use, but how you weave a crucial operational element through your planning.

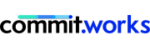

A study done by Accenture found the top miners of our time are:

- Missing production targets frequently, an industry-wide $64bn revenue loss over the last 5 years; and

Root cause analysis found that:

- One; target setting was suboptimal, and

- Two; actual performance didn’t match expectations.

No operation can afford to leave that much value on the table.

So, how do miners improve productivity using technology?

The answer for most: Deploy a new operating system.

From Rio Tinto’s Safe Production System (RTSPS) to BHP’s Operating System (BOS),and all the miners in between who are engaging big four or independent consultants, one theme remains – change is hard, and too often, investment doesn’t deliver expected returns.

The Challenge? Attempting to drive and sustain change and high-performance through your people.

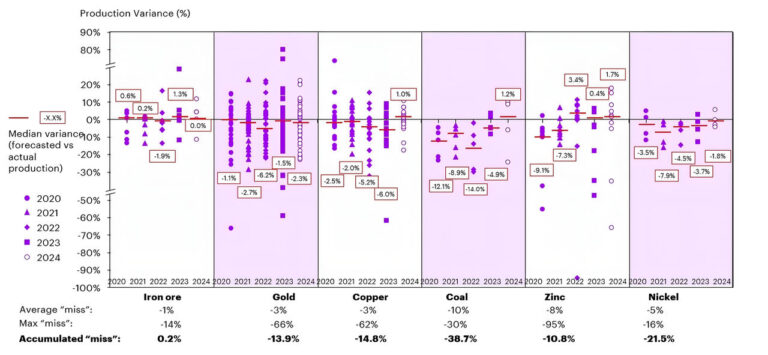

Too often, miners expect operational leaders to deliver success. But pushing for high performance can have the opposite effect. It can push teams into one of two unhelpful states — the Anxiety Zone (“I must hit my targets at any cost”) or the Comfort Zone (“I’m unsure what to do, so I do nothing”).

Enter the Digital Operating System – the smart operating framework and platform for your mine. A Digital Operating System needs a technology stack that supports:

- Rigour – Discipline in Process + Visibility of Performance + Accountability for Outcomes

- Routine – Structured, Time-Based Cadence of Behaviors and Processes

It translates high-level plans into frontline action through a structured cycle of Plan, Do, Check, and Act.

This isn’t bureaucratic busywork; it’s the backbone that connects strategy to execution.

A well-designed operating system that leverages technology ensures that every shift, every crew, every leader knows the plan. The plan can be executed against clear targets that cover the whole of mine. Progress can be checked, and action taken to combat huge production losses, inefficiencies, or safety implications.

Here it is – the Golden Thread that will help you deliver operational excellence. Let’s revisit the root cause of value being left on the table.

#1 Suboptimal Target Setting

Most operations focus narrowly on production KPIs, often overlooking broader metrics of tasks that drive end-to-end performance of the critical path.

These tasks or activities are commonly referred to as enabling activities. These interactions between departments, people and equipment don’t necessarily deliver you meters, ore tons, or production BCMs—but are equally, if not more important at times, than dig rate, or machine utilisation.

Current State: ‘Whole of Mine’ KPIs aren’t tracked because it’s hard work and requires lots of manual data input ‘after the fact’.

Much of the data from the broader operational perspective isn’t found on machines in Fleet Management or SCADA systems, or in enterprise platforms like an ERP or mine planning and scheduling tools.

Asking execution teams to fill out a paper form at the end of a shift isn’t a priority.

The laborious effort of manual data entry, coupled with high variability in shifts, or over the course of execution week, creates a natural deterrent.

Additionally, this data may not be accurately aligned with operating models. Operations can’t reliably track and execute shifts or work weeks in enterprise level work management or resource planning tools (ERP) because they:

- aren’t built for the deskless workforce,

- lack configuration flexibility to meet data capture needs; and

- have limited mobility – a necessity to capture the right data at the right time.

So, What KPIs Should I Focus On?

Where should modern mining operations focus to drive performance?

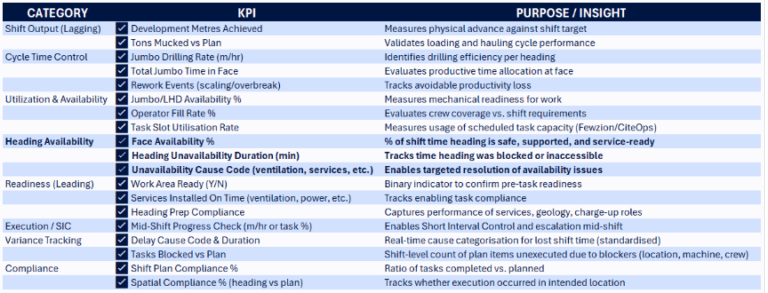

In an underground mine, the below table highlights some of the critical KPIs the highest performing operations are digitally tracking every day:

Unplanned heading inaccessibility due to scaling, ventilation, water, or services, is a consistent root cause of missed development meters, lost drilling hours, and cascading delays.

By leveraging a technology tool like CiteOps as the source of truth, the operation can then manage more effectively:

- Task allocation (planned vs actual)

- Delay logs (reason vs duration) and compare the operations data to fleet management data

- Face readiness status

- Unavailable headings and the trends

This model further supports and unlocks high-quality daily shift reviews, SIC cycles, and weekly trend reporting.

The next challenge is how to translate strategy into frontline execution. And the answer is simple: through disciplined shift handover, prestart meetings, and daily reviews.

Here’s what high-performing operational leaders consistently ask their crews—before they head underground, during the shift, and at end-of-day debriefs:

Pre-Shift KPI Checklist for Supervisors (CiteOps/Commit Works Style)

Mid-Shift (Short Interval Control) Questions:

End-of-Shift Review Questions:

#2 Actual performance didn’t meet expectations

In Part 2, coming soon, we will unpack “The Anatomy of a High-Performing Mine – The Hidden Challenges That Will Be Obvious Once You’ve Read This” and the levers you can pull at your open cut operation to maximise high-performance.

What do you think they are?