BY IAN JONES,

COMMIT WORKS HEAD OF PRODUCT

As formal mining education pathways shrink, the industry risks losing the expertise that gives operational data meaning. Capturing and transferring practitioner knowledge is now essential to unlocking real value from AI.

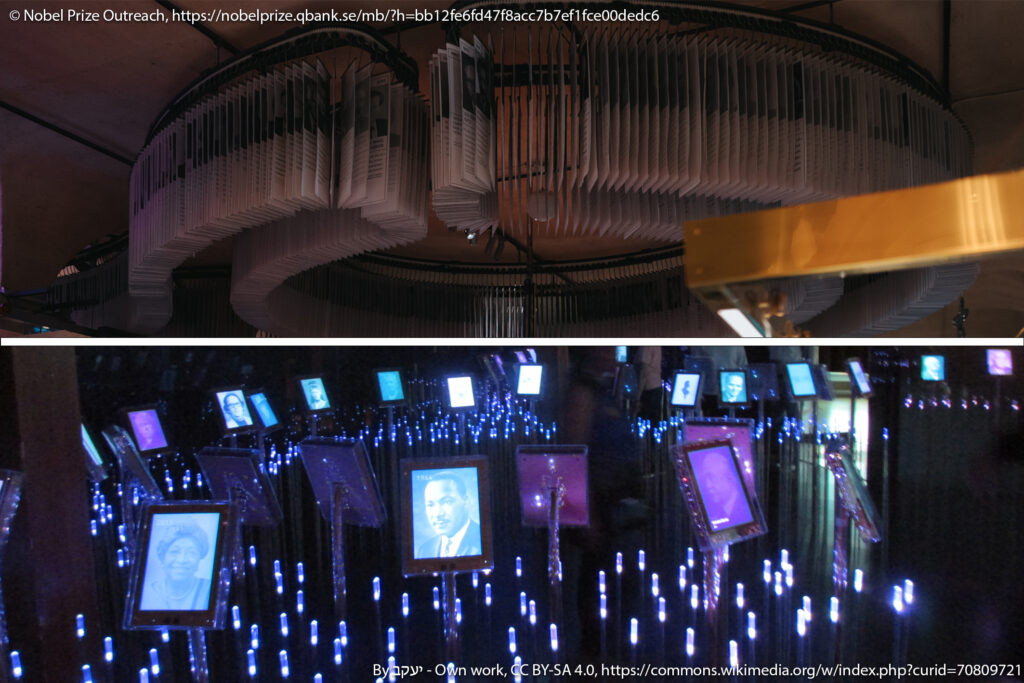

Keeping the theme from part one, have a look at these images. They are both from museums associated to the Nobel Prize. Many of us instinctively correlate the Nobel Prize with peace, but the truth is prizes are awarded across diverse areas of life and study including science, engineering, economics, literature and medicine.

I believe the images, as I have shown them, represent a summary of the achievements of each recipient. To a casual observer they may not fully portray the impact of the works of these leaders in their fields. The first shows the Stockholm Museum. Cards hanging from the ceiling depict Nobel Prize recipients, recording individual achievements with some context. The second is of the Oslo Museum. An interactive, digital display allows patrons to engage with similar data about recipients. When you first enter the museum, this can be overwhelming but once you start to track a particular field of endeavour, these tools provide a wonderful summary of the thinking behind each achievement.

Expert knowledge is essential for real operational impact.

What does this have to do with AI and mining? I believe we can learn a great deal from these images. The collected data reflects the expertise each recipient bought to the world of knowledge.

As we see Universities continue to scale back dedicated Mine Engineering programs, the depth of academic knowledge imparted to newcomers to the industry is lessened. This places a great responsibility on those of us still in the industry to preserve, structure and transfer learnings from academia and practice.

How do we, as experienced practitioners, ensure the next generation of mining professionals can access and build on this knowledge rather than relearn it through failure? I’ve been very fortunate in my mining career to work for, and with, some industry visionaries. Listening to how they think and observing how they work has built my knowledge of many facets of the mining industry.

Learning from experience.

I was first introduced to mining through data collection and reporting whilst working for an early business intelligence startup called CorVu. We worked with MIM (now Glencore), Pulse Mining and others to build reports on mine and equipment performance. When I started, I wouldn’t have known the difference between a dozer and a digger! But I was keen to listen, and I learned a great deal.

A determining career change was being to join Thiess’ Resource Development Group. There are few opportunities to join an internal think tank combining years of knowledge from across an industry. Nick Jukes had taken his vision and assembled a fascinating team of experts. My contribution was a small but pivotal system that still operates, in a revised form, on Thiess Mines 20 years later. Along the way I learned Pit to Port on an Indonesian Mine, Drill and Blast on a Hunter Valley Mine, Data Warehousing across many operations, Asset Maintenance of Fixed and Mobile Plant, and Fleet Management on coal operations.

After my time at Thiess, I could apply the knowledge and experience gained at Deswik (underground hard rock mining), RPMGlobal (underground coal mining) and iVolve (fleet management) before joining Commit Works. The guidance of Adam White, Wayne Romer and Jay Gillon at Deswik helped me translate open pit learnings to an underground context. A practical example that experts can accelerate learning on any topic.

As a business analyst I would never have been able to design or deliver these solutions without the contributions from experts I had access to. Once I acknowledged I didn’t know it all, I could learn a great deal. I was then able to design and deliver some great solutions to the market.

Bridging knowlege and innovation.

Now, Commit Works gives me the opportunity to deliver a solution that marries 12 years of development with my experience. Together, we will deliver a better operational planning solution. I enjoy taking a team of very strong technicians on a journey of learning, sharing the theoretical and practical knowledge I’ve gained along the way.

I hope others are afforded the opportunity to listen first, rather than assume they know the solution or have the answers. After all, effective business analysis requires a careful review of historical solutions, understanding the ‘as-is’ state and using this data to derive a ‘to-be’ state that meaningfully improves on the past.