AI and Machine Learning in Mining: Why Granular Data Matters

In recent years, the application of Artificial Intelligence (AI) and Machine Learning (ML) to revolutionise the industry has been a hot topic. Many discuss the importance of data in this transition, but few recognise the required granularity to support it.

Since 2010, miners have invested in ERP (finance and asset management), mine planning and FMS (with autonomous capabilities). With planning and real-time data capture covered, a critical gap remains in integrating operational planning and execution data.

The importance and impact of this data, still commonly managed using whiteboards, PowerPoint, Excel or paper, has become increasingly clear.

Mining Activity Conformance to Plan (CtoP) and Its Limitations

Conformance to Plan (CtoP) reporting of Mining Activities often excludes enabling or development activities essential for success. Traditional CtoP reporting highlights issues but lacks context. Operations apply insufficient rigour to managing enabling tasks as is required for effective collaborative planning. For AI/ML solutions to suggest improvements, they require deeper, more granular insight than what traditional short-term mine planning tools offer.

A mine plan optimistically lists key tasks to be completed, and once reviewed with all parties, establishes a baseline of critical path items. These items form the measurable data set for KPIs. However, KPIs and plan variances are diagnostic, not actionable. Supporting data that exposes contributing factors and enables tasks to be scheduled, assigned, executed, and evaluated is needed for action.

Expanding the Mine Plan to Capture All Mining Activities

An effective plan must include all work required to deliver critical path items. It should also recognise the impact of all processes on the schedule. Many sites do not complete this scheduling work, assuming other teams will complete tasks. Mining operations cannot understand true resourcing required without considering all tasks. Capturing this information on whiteboards, spreadsheets or paper hinders future analysis, especially by AI tools needing a data warehouse for ML analysis.

Data that represents progress to plan must be captured. In mining, many critical path items can be updated from third-party tools like FMS. Capturing enabling task progress is complex and requires an IT solution. Operations must compile these inputs from varying sources into a data lakehouse to provide a platform for rules-based and ML analysis. ML can then detect data trends useful for generative, predictive or agentic AI, and support real-time schedule optimisation.

Integrating Systems to Unlock Real-Time AI in Mining

AI will continue to impact how we view plans and their execution. The key is ensuring all relevant data is captured and connected so ML can identify useful trends, highlight opportunities and reveal issues early.

To support effective reporting and analytics, teams must capture data, and establish relationships in real-time, for rapid decision making. Integrating ERP and FMS with operational execution data will provide richness to power advanced AI/ML.

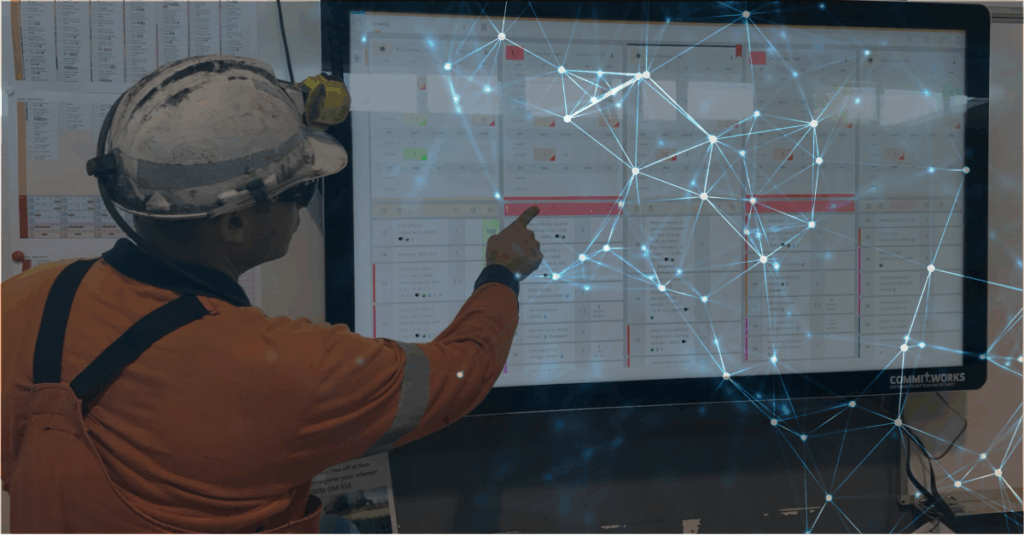

Capturing Critical Execution Data with CiteOps

CiteOps is an integrated planning and execution software solution. This solution improves productivity by capturing short range plans and executional activities while fostering continuous feedback loops.

This enterprise-grade operational planning and execution platform specifically designed for mining and metals companies enables:

- Unified planning and execution

- Dynamic scheduling

- Centralised resource management

- Real-time decision making and

- Mobile execution