Integrations

Integrating critical IT/OT and planning systems

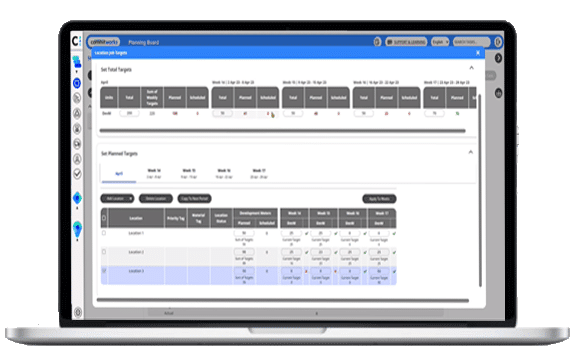

Our goal is to ensure the intentions of management and planners are reflected in the shift to shift work executed by the frontline team.

To achieve this sustainably it’s important that we connect our software with the tools used by technical services, engineering, maintenance, HR and others – so that all work on-site can be effectively scheduled and coordinated.

At the other end we pull frontline operating data from machines and fleet management systems so that tasks in our software are updated with “actuals” data from machines.

Connecting your IT/OT systems

We have a number of ways of connecting our software to other systems:

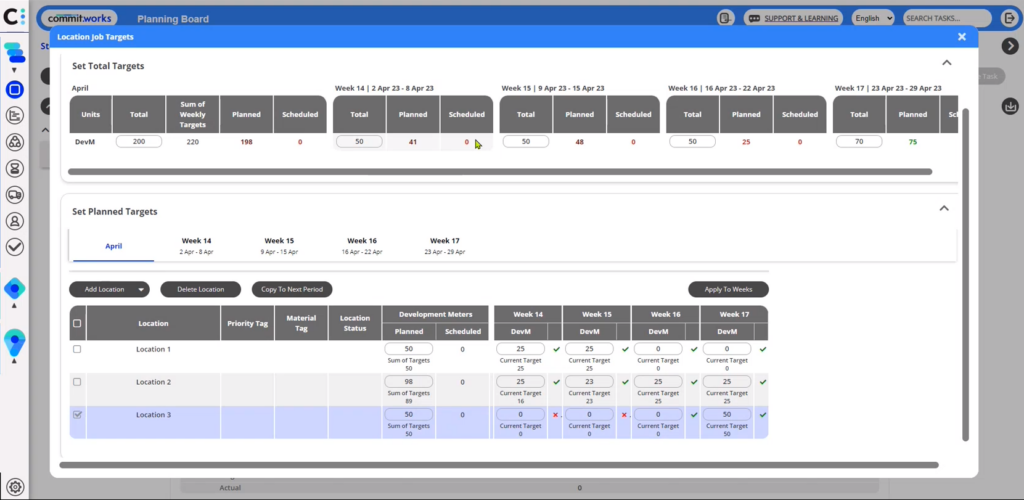

CiteOps – Smart Imports

Integration Upstream Planning i.e. Micromine Spry or Deswik. Sched via Excel files as needed:

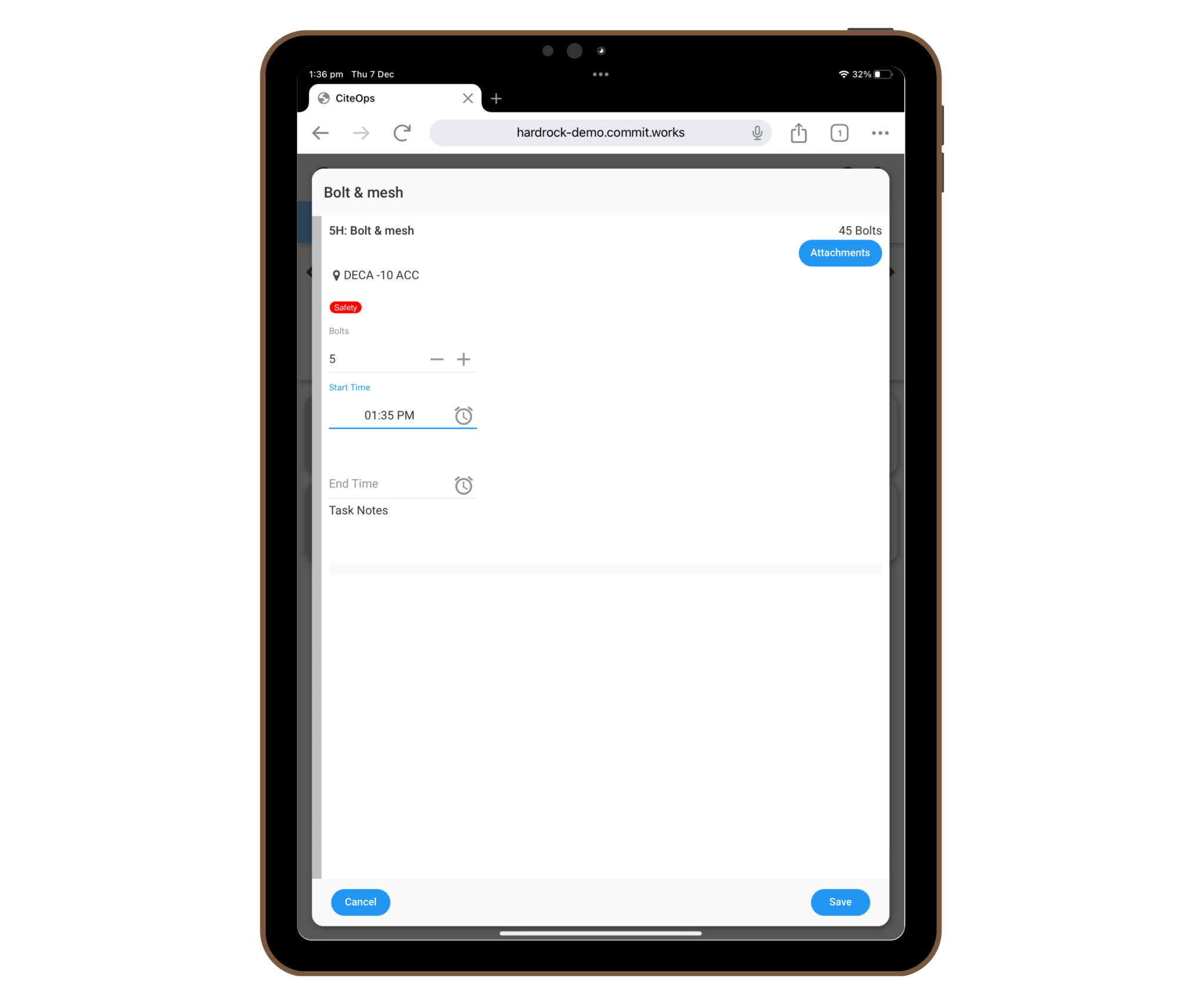

- Import longer-term location-based targets from technical services to drive operations scheduling in CiteOps.

Integration other third party software via Excel files or SQL Databases as needed:

- Import Tasks

- Import Users

- Import Locations

- Import Equipment

- Import Roster

CiteOps – REST API

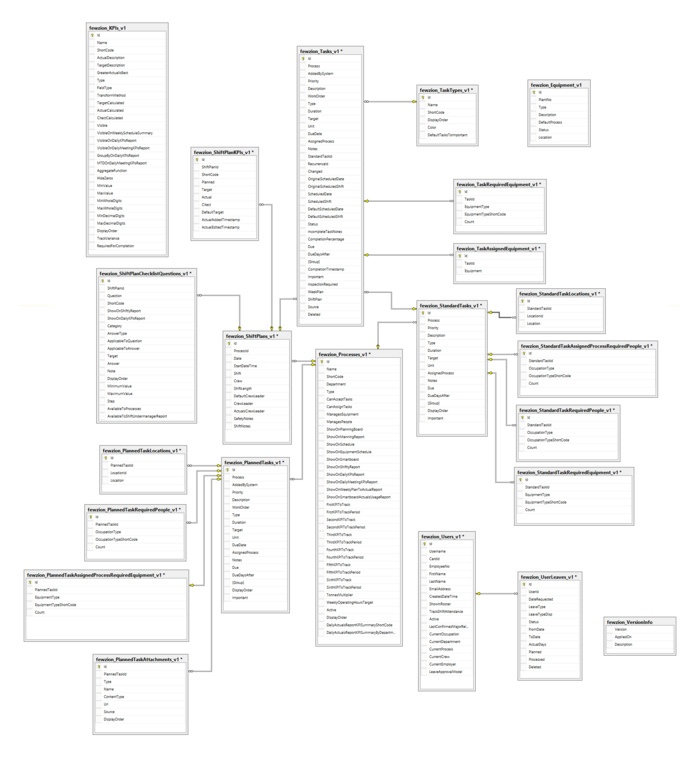

Real-time Integrate third party software as needed

- Populate CiteOps maintenance schedule and workorders from ERP systems such as SAP, Oracle

- Populate CiteOps roster information and skills detail from HR system

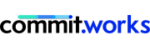

- Populate CiteOps production actuals from fleet management systems or Digital PLODs when these are available

- Customer Integration Teams, or 3rd party System Integrators (SIs) can push and pull data from CiteOps in real-time using our standard Web API

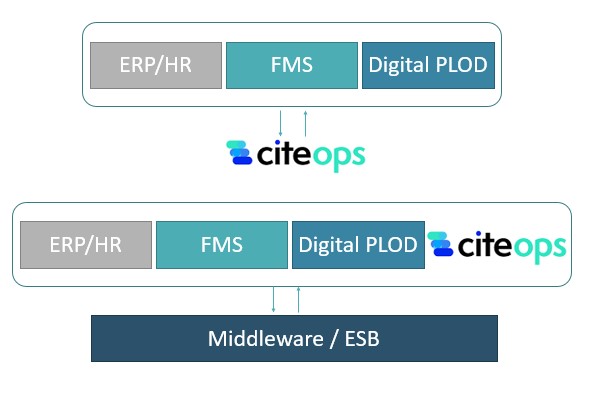

- Integrations can interface with the CiteOps API point-to-point or via middleware

- Modern, Open Approach

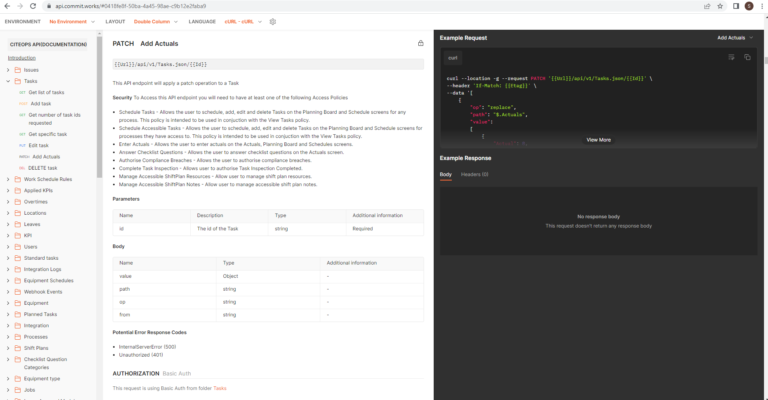

- RESTful API

- JSON Format

- Token-based Authentication

- Our Web API offers secure external access to all CiteOps functionality and is fully documented at https://api.commit.works

Note: Commit Works does not integrate directly with 3rd party systems or middleware, but CiteOps ships with comprehensive Web APIs for integrators to use

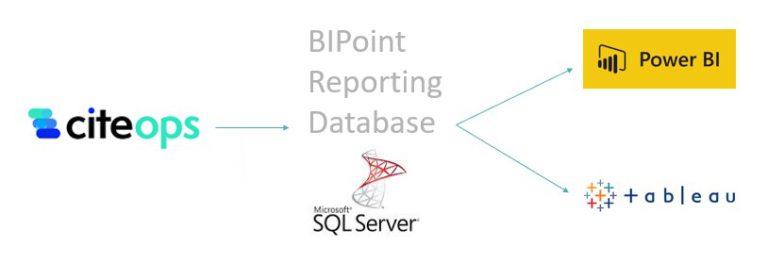

CiteVis – BIPoint Reporting Database

Integrate third party software via direct SQL connections:

- CiteVis BIPoint database where appropriate can populate downstream reporting and accounting systems with CiteOps operational data

Connect your management operating system

In a related but different way we also embed our software into your management operating system (MOS), Business Process Framework (BPF), Lean, Six Sigma, 7/21 or “wiring”, to create what we call your ‘Commitment System’ – which ensures the software supports and improves the way you plan, do, check and act on frontline work.