24/48 Hour Schedule

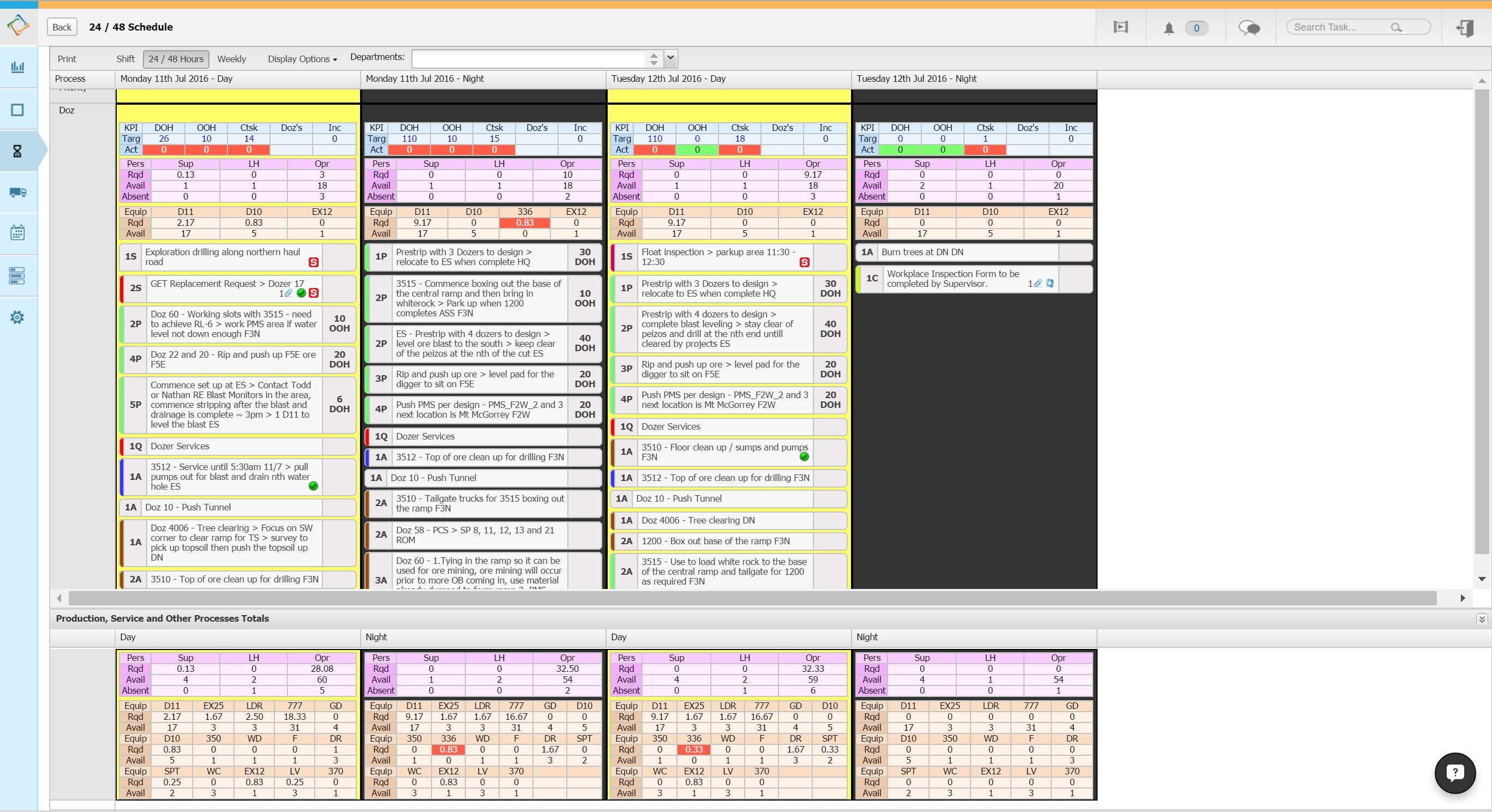

The 48-hour schedule screen provides planners and schedulers a holistic view of the KPIs, resources and tasks for every process in the schedule, for the next 48 hours.

The 48-hour schedule screen also allows inter-shift plan actions such as moving and copying of tasks, notes, and other items.

Write access is given to users with the role of the scheduler.

The left side of the 48-hour schedule screen holds the list of processes which label each row. Each column in the bulk of the screen represents a specific shift for a specific day. This screen shows much of the same information contained in the Process Plan, but for all processes. Of course, here the focus is on the scheduling and approval of specific tasks.

Displayed are lists of personnel required and available as well as equipment required and available. Red highlights mark requires that currently cannot be met because of insufficient resources allocated to the process.

The 48-hour schedule also allows for the inclusion of “shadow” processes which are tied to a production process so that dependencies can be tracked and accommodated—for instance, the servicing of equipment.

Colour-coded icons allow the planner to tell at a glance which items are pending approval, have already been accepted or already rejected. A single click can modify the status of any one plan item.

The bottom section of the screen holds the production totals for each shift across all processes, including figures for both personnel and equipment that are required and available.