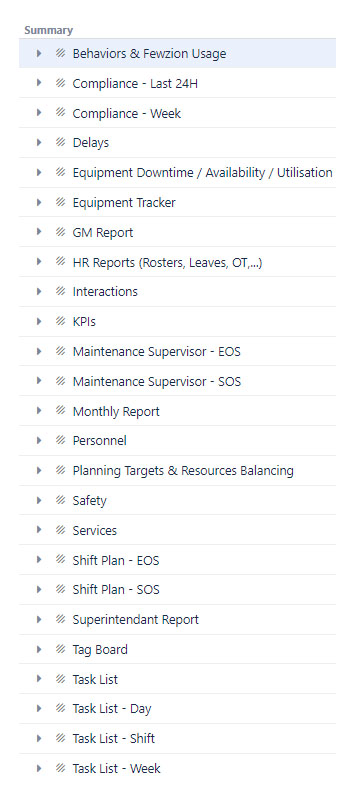

CiteOps Reporting Capabilities

Commit Works is a powerful operations planning and execution platform designed to help mining teams close the continuous improvement loop, effectively boosting performance and reducing waste. With up-to-date data encompassing all essential aspects of the operation, tailored to end users, teams can operate more efficiently, productively, and safely. The system’s advanced reporting capabilities facilitate regular performance reviews, while comprehensive data analytics help teams understand the root causes of plan variances and on-site issues.